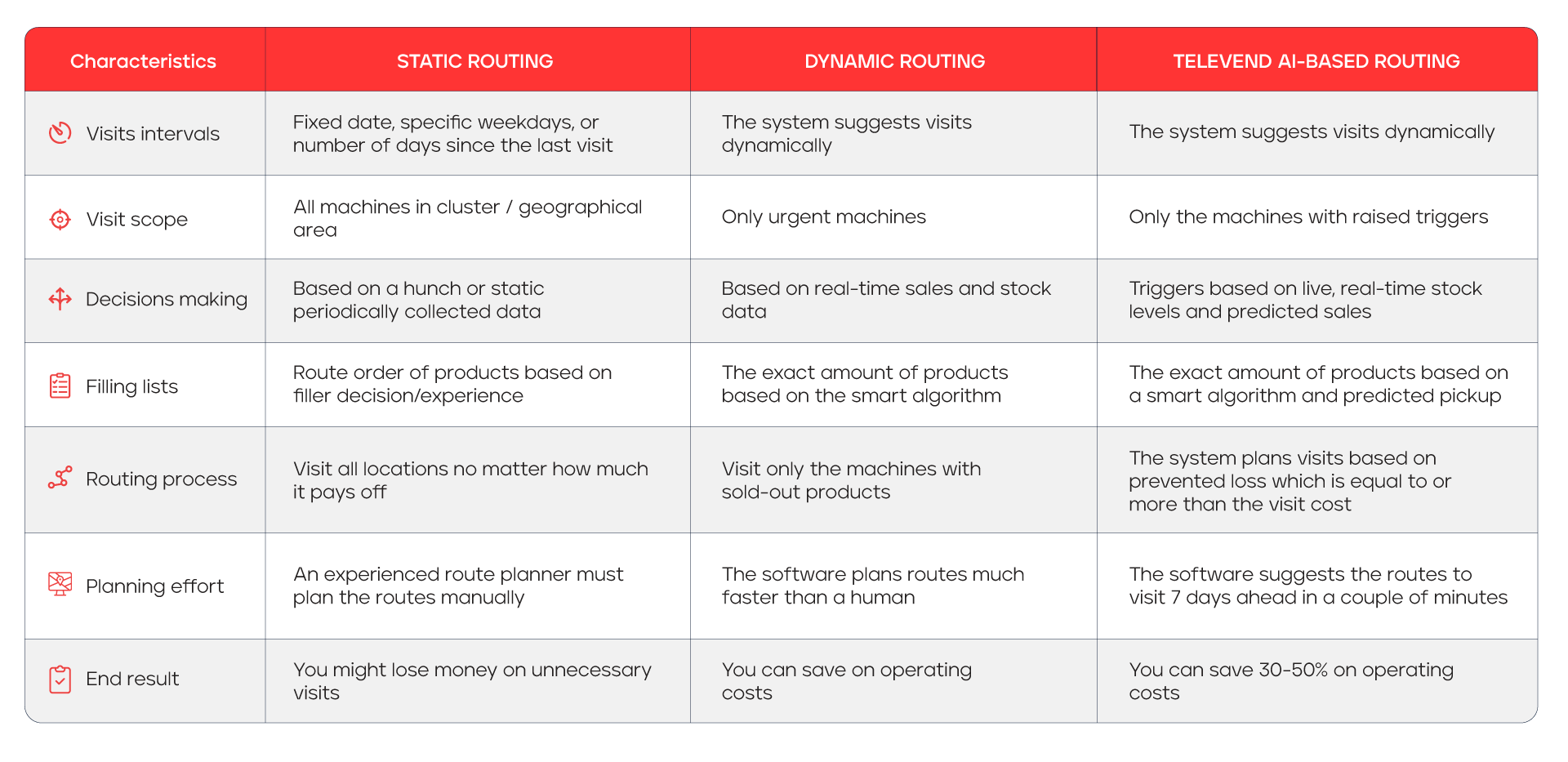

One of the most essential operations in vending is route planning for merchandisers. How businesses do the routing can greatly affect their logistic efficiency, customer satisfaction, and operational costs. So, no wonder companies do whatever they can to optimize this business area. Over the years of optimizations and technological advancement, three types of vending route planning have developed: static, dynamic, and the most advanced – AI-based and automatic routing. You can read more about each type in this post.

Static Routing

Traditionally, vending operators used static routing for the machine restock visits. It is a process of scheduling routes for machine visits on the same days in the week or at exact intervals. This planning is typically done based on factors such as machine location and general insights into product demand based on historical data.

There are two typical cases of static planning. The first one is manual planning, where the planner uses only pen and paper or a simple table tool like Excel. The other type is planning for offline machines that are tracked by some central system like ERP. In such cases, data would need to be collected manually from the vending machines at each location by using a handheld device to scan inventory levels and sales data. This data must then be uploaded to a central system when an internet connection is available.

However, static planning has proven to have many drawbacks. One of the main issues with static routing is inflexibility, making it difficult to adapt to changing market conditions, such as shifts in customer preferences or machine breakdowns.

For instance, a vending operator may have planned a route based on past data that shows high demand for a particular product at a certain location, but if the demand drops suddenly, the operator may end up wasting resources by overstocking that machine.

On the other hand, if a product suddenly becomes popular, static route planning may not be able to adjust quickly to meet the increased demand, which could result in stockouts and dissatisfied customers. Finally, the results are wasted products and increased costs for the vending operator.

Moreover, handheld devices used for data collection from offline machines are expensive, difficult to carry, and hard to maintain.

Dynamic Routing

Dynamic routing is a far more advanced system than static routing. Dynamic routing typically relies on telemetry within the vending management systems (VMS) to collect and analyze real-time data and optimize delivery schedules.

So, unlike static route planning, which relies on predetermined schedules and data, dynamic routing takes into account current factors such as real-time machine inventory levels, live sales transactions, and company business goals to optimize delivery schedules.

For example, a dynamic routing system uses real-time data to determine which machines are running low on popular products, so a company can prioritize these machines for a restock ahead of others that may have a surplus of inventory. This can help maximize sales and revenue while also ensuring that customers are satisfied with the product selection and availability.

Moreover, a dynamic system can also detect machines that are not critical to visit, omitting them from a restock schedule. By minimizing unnecessary trips and reducing overstocking, dynamic routing can help improve inventory management and reduce operational costs.

Additionally, dynamic routing systems often use traffic data to create optimized delivery routes that reduce fuel consumption and minimize travel time, thus significantly boosting profit margins. Overall, all these cutbacks can help reduce fuel consumption, labor costs, and vehicle wear and tear.

Televend’s AI-Based and Automatic Routing

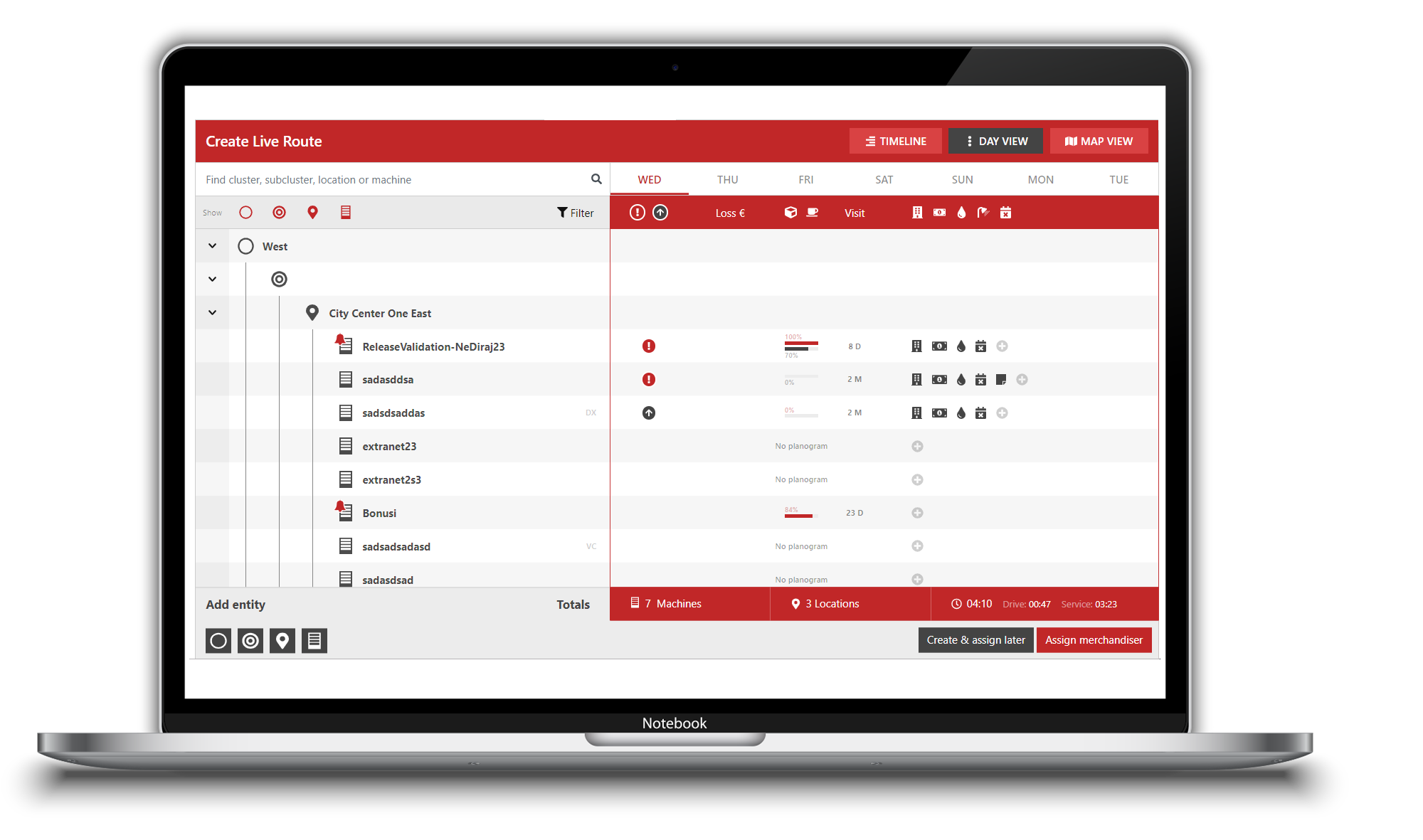

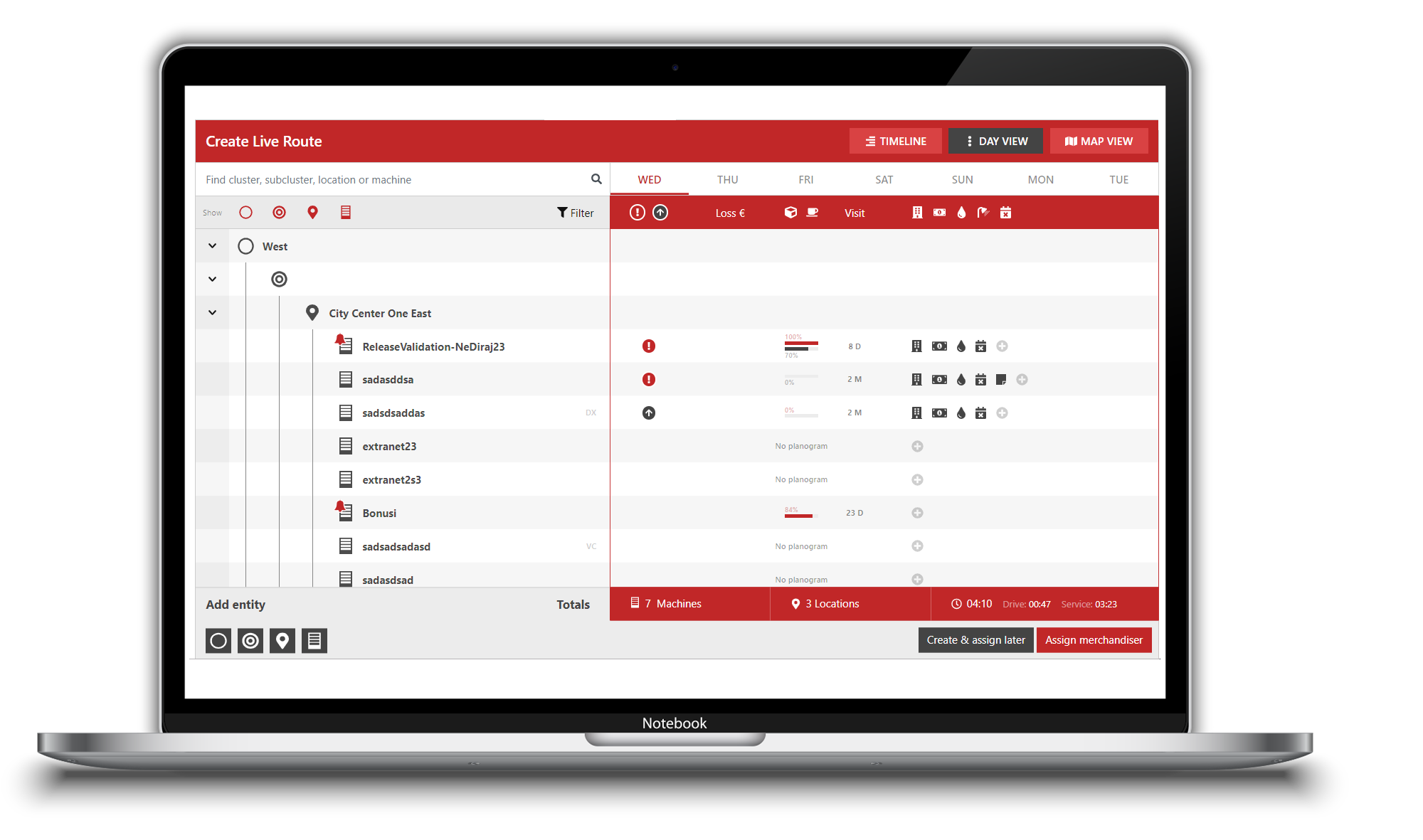

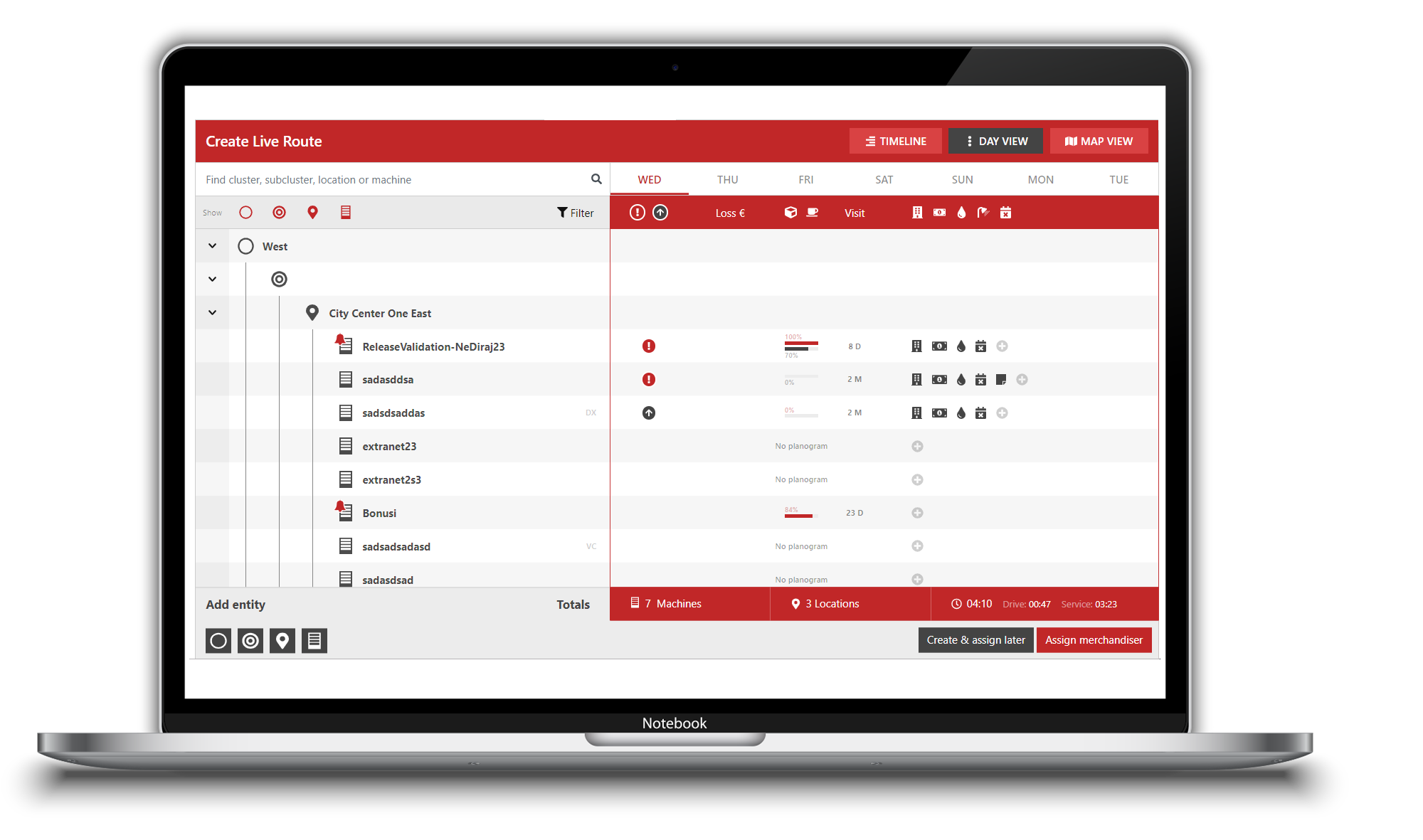

Televend has brought dynamic routing to a whole new level. It is based on AI technology, which analyzes historical sales and inventory data and predicts which machines will be critical to visit in the NEXT period. This way, route planners can schedule the itinerary for a whole week in just a few minutes. This cuts their planning time, making their work more efficient and removing human error.

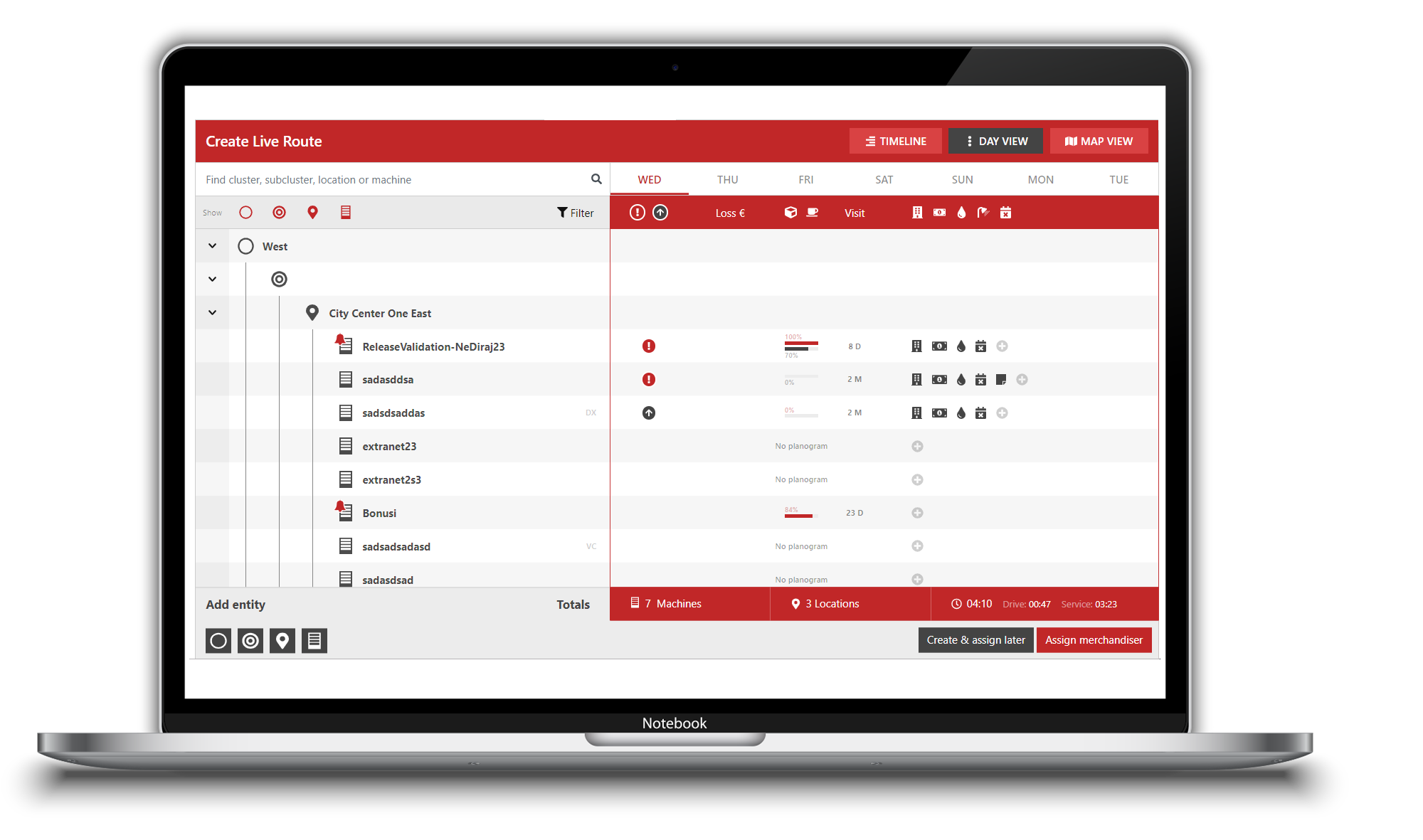

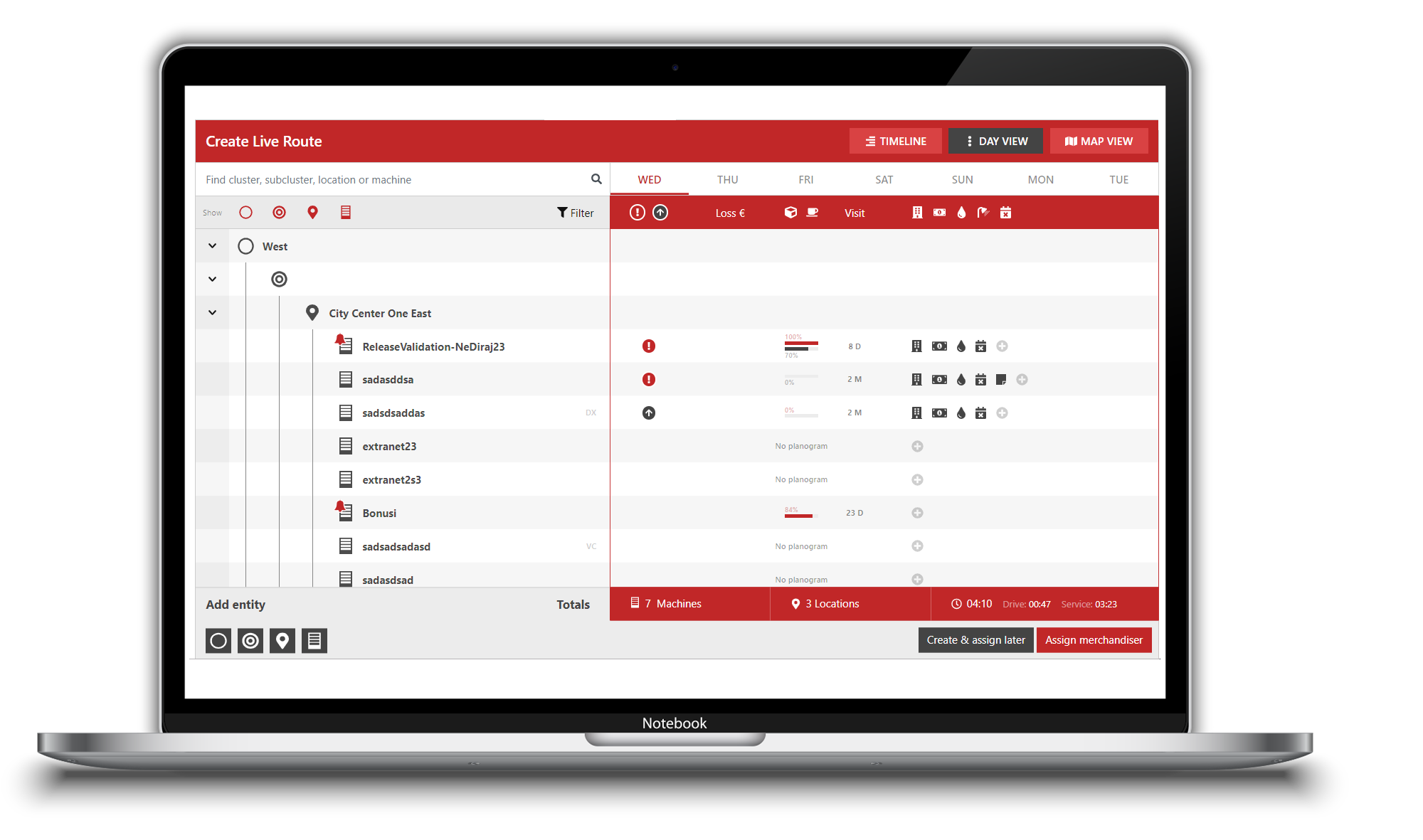

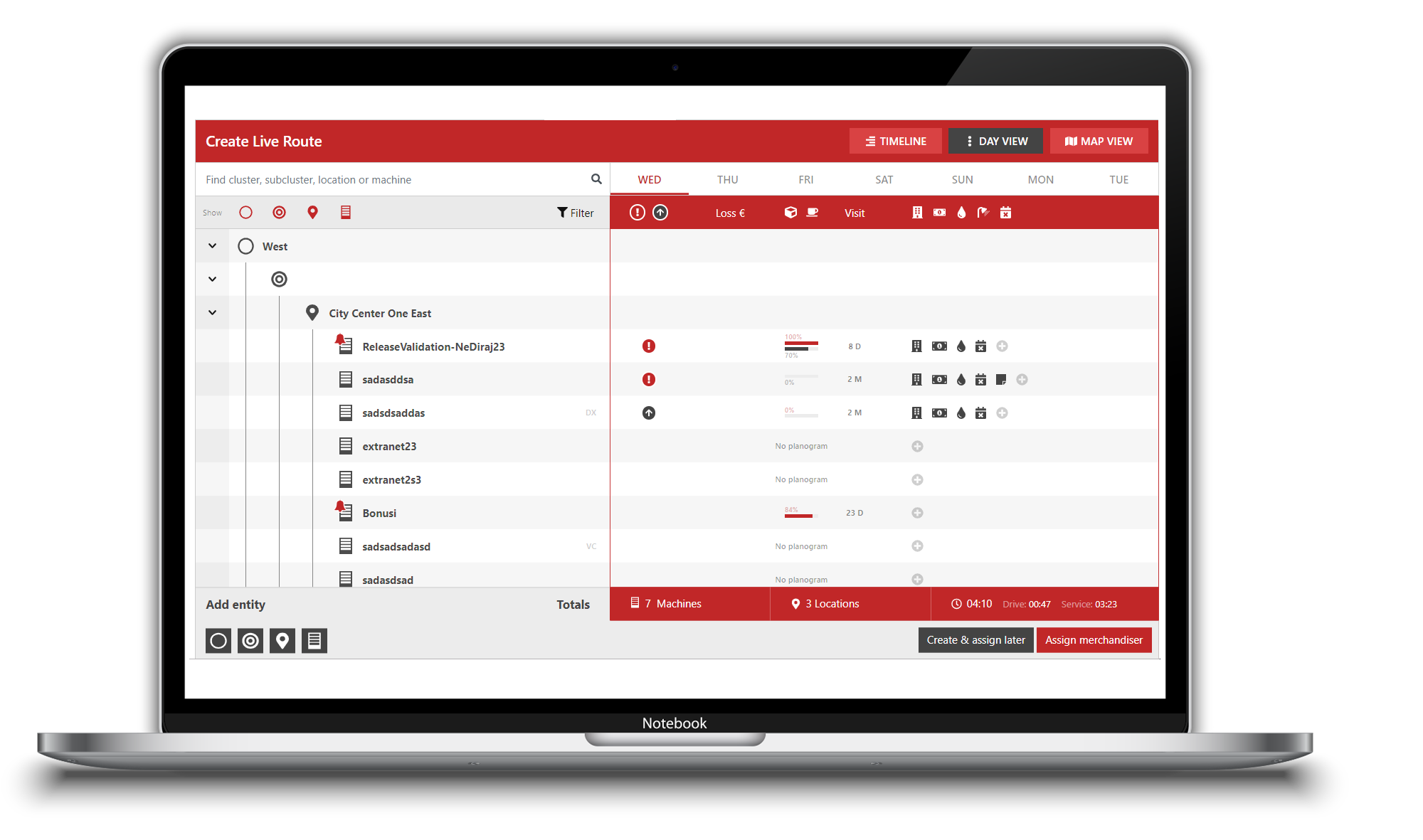

What does the route planning with Televend look like?

Once you configure the system, the process is streamlined. After the initial setup (e.g., locations, trigger rules) and the machine learning process, the system will plan the most optimal route for the merchandiser within the machine selection. Moreover, the planner can choose multiple geographical areas (e.g., clusters) and multiple merchandisers and the system will “mix and match” for the most optimal visit plan. This way, the system will optimize the routes, aiming at the best profit margin within the operational costs.

Moreover, the system’s accuracy ensures that only the machines that need to be visited are visited. So, if a visit to the machine costs you 20 €, and you will earn only 10 € if you restock it at that moment, the system will show that the machine is not critical. This way, operators can cut unnecessary visits, leading to more than 30% fewer operational costs.

Since the first version, Televend upgraded route planning software, so now it can create routes automatically. Thanks to an algorithm that considers the number of available merchandisers, their work hours, and their priorities before allocating the route to the best-placed merchandiser – the system does everything without human interaction.

This means that operators can delegate a big chunk of their iterative work to the AI and focus on more strategic things. Also, when employing new staff, an automatic routing system allows operators to consider more inexperienced workers as well as they can do the job with a click of a button. This can speed up the onboarding process making new employees fully productive more quickly.

Not to mention that Televend does all that route planning for technical staff as well. It collects technical events and errors from various channels, such as events from the machine, customer calls, and technicians from the field. Then, it prioritizes tasks and dispatches the technician using the same AI technology for planning their routes. This way, operators can service machines without delay and maintain their reputation.

If you want to learn more about how Televend can help you maximize your profits and cut operational costs, feel free to schedule a demo with our team.

One of the most essential operations in vending is route planning for merchandisers. How businesses do the routing can greatly affect their logistic efficiency, customer satisfaction, and operational costs. So, no wonder companies do whatever they can to optimize this business area. Over the years of optimizations and technological advancement, three types of vending route planning have developed: static, dynamic, and the most advanced – AI-based and automatic routing. You can read more about each type in this post.

Static Routing

Traditionally, vending operators used static routing for the machine restock visits. It is a process of scheduling routes for machine visits on the same days in the week or at exact intervals. This planning is typically done based on factors such as machine location and general insights into product demand based on historical data.

There are two typical cases of static planning. The first one is manual planning, where the planner uses only pen and paper or a simple table tool like Excel. The other type is planning for offline machines that are tracked by some central system like ERP. In such cases, data would need to be collected manually from the vending machines at each location by using a handheld device to scan inventory levels and sales data. This data must then be uploaded to a central system when an internet connection is available.

However, static planning has proven to have many drawbacks. One of the main issues with static routing is inflexibility, making it difficult to adapt to changing market conditions, such as shifts in customer preferences or machine breakdowns.

For instance, a vending operator may have planned a route based on past data that shows high demand for a particular product at a certain location, but if the demand drops suddenly, the operator may end up wasting resources by overstocking that machine.

On the other hand, if a product suddenly becomes popular, static route planning may not be able to adjust quickly to meet the increased demand, which could result in stockouts and dissatisfied customers. Finally, the results are wasted products and increased costs for the vending operator.

Moreover, handheld devices used for data collection from offline machines are expensive, difficult to carry, and hard to maintain.

Dynamic Routing

Dynamic routing is a far more advanced system than static routing. Dynamic routing typically relies on telemetry within the vending management systems (VMS) to collect and analyze real-time data and optimize delivery schedules.

So, unlike static route planning, which relies on predetermined schedules and data, dynamic routing takes into account current factors such as real-time machine inventory levels, live sales transactions, and company business goals to optimize delivery schedules.

For example, a dynamic routing system uses real-time data to determine which machines are running low on popular products, so a company can prioritize these machines for a restock ahead of others that may have a surplus of inventory. This can help maximize sales and revenue while also ensuring that customers are satisfied with the product selection and availability.

Moreover, a dynamic system can also detect machines that are not critical to visit, omitting them from a restock schedule. By minimizing unnecessary trips and reducing overstocking, dynamic routing can help improve inventory management and reduce operational costs.

Additionally, dynamic routing systems often use traffic data to create optimized delivery routes that reduce fuel consumption and minimize travel time, thus significantly boosting profit margins. Overall, all these cutbacks can help reduce fuel consumption, labor costs, and vehicle wear and tear.

Televend’s AI-Based and Automatic Routing

Televend has brought dynamic routing to a whole new level. It is based on AI technology, which analyzes historical sales and inventory data and predicts which machines will be critical to visit in the NEXT period. This way, route planners can schedule the itinerary for a whole week in just a few minutes. This cuts their planning time, making their work more efficient and removing human error.

What does the route planning with Televend look like?

Once you configure the system, the process is streamlined. After the initial setup (e.g., locations, trigger rules) and the machine learning process, the system will plan the most optimal route for the merchandiser within the machine selection. Moreover, the planner can choose multiple geographical areas (e.g., clusters) and multiple merchandisers and the system will “mix and match” for the most optimal visit plan. This way, the system will optimize the routes, aiming at the best profit margin within the operational costs.

Moreover, the system’s accuracy ensures that only the machines that need to be visited are visited. So, if a visit to the machine costs you 20 €, and you will earn only 10 € if you restock it at that moment, the system will show that the machine is not critical. This way, operators can cut unnecessary visits, leading to more than 30% fewer operational costs.

Since the first version, Televend upgraded route planning software, so now it can create routes automatically. Thanks to an algorithm that considers the number of available merchandisers, their work hours, and their priorities before allocating the route to the best-placed merchandiser – the system does everything without human interaction.

This means that operators can delegate a big chunk of their iterative work to the AI and focus on more strategic things. Also, when employing new staff, an automatic routing system allows operators to consider more inexperienced workers as well as they can do the job with a click of a button. This can speed up the onboarding process making new employees fully productive more quickly.

Not to mention that Televend does all that route planning for technical staff as well. It collects technical events and errors from various channels, such as events from the machine, customer calls, and technicians from the field. Then, it prioritizes tasks and dispatches the technician using the same AI technology for planning their routes. This way, operators can service machines without delay and maintain their reputation.

If you want to learn more about how Televend can help you maximize your profits and cut operational costs, feel free to schedule a demo with our team.

Table of Contents

Subscribe To Our Newsletter

Sign up to our monthly business newsletter for useful articles, tips, and tricks for boosting your business success.

By subscribing, you consent to receive email marketing communications from Televend. For more

information please read our Privacy Policy.